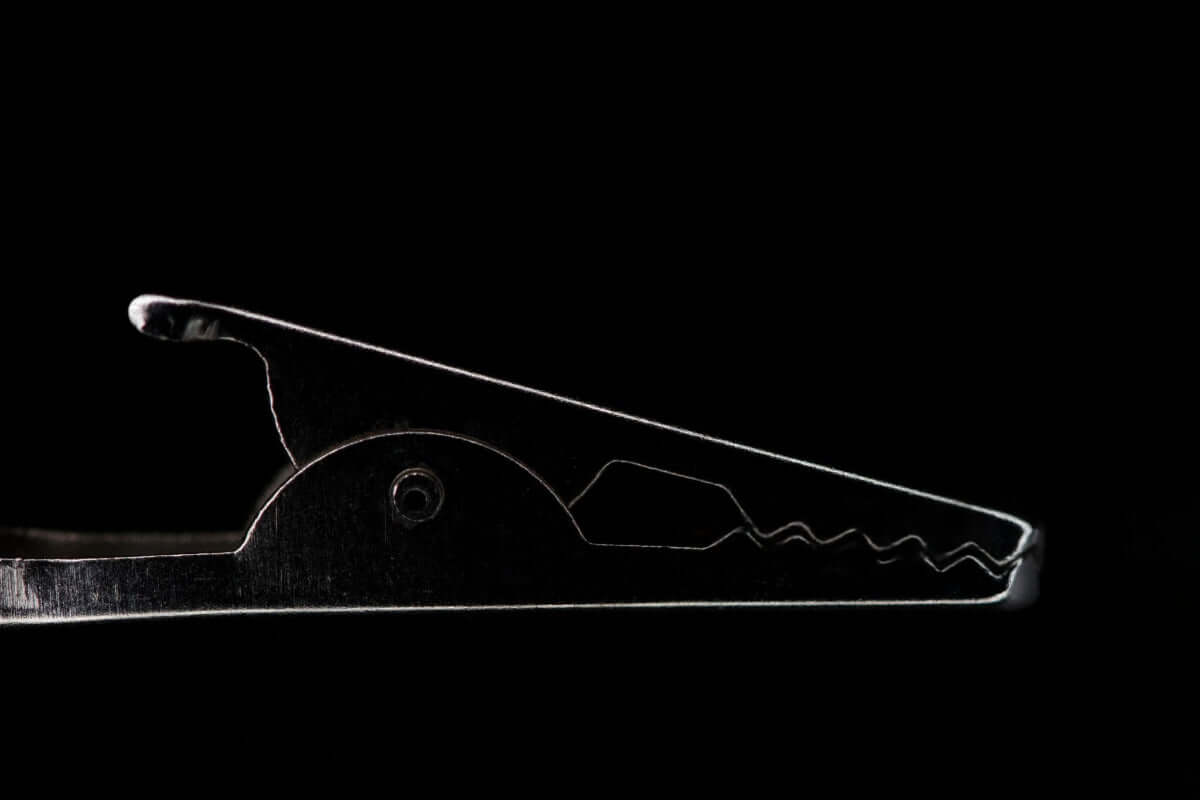

The Leading Alternative to Mueller Electric Clips

Telewire Tech provides 1:1 mechanical and electrical interoperability for the most widely used industrial test clips in the global market.

Eliminate Sourcing Risk

Reduce your Bill of Materials (BOM) cost without compromising on industrial specifications. Access our complete mapping database to find the equivalent clips

Engineering Capabilities

Precision manufacturing solutions optimized for durability and compliance.

Custom Wire Harness

Specialized in multi-branch harnesses for automotive and industrial automation. Built with UL-rated materials and 100% Hipot tested.

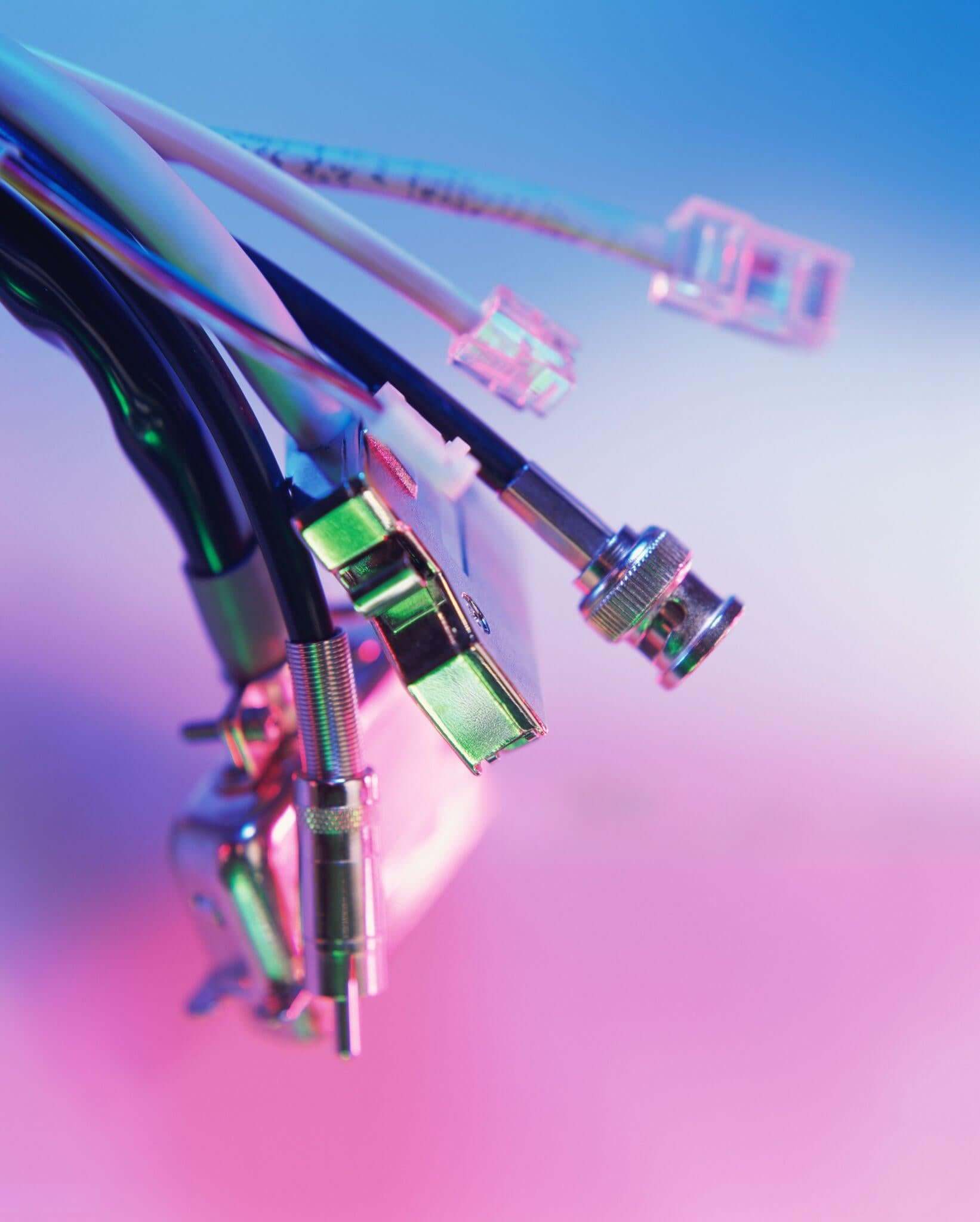

Cable Assembly

Overmolded, shielded, and ruggedized assemblies. Providing custom solutions for Medical and Telecom applications.

Custom Test Leads

High-precision testing clips for industrial applications, fully compatible with Mueller Electric clips for seamless assembly.

Our One-Stop Custom Manufacturing Process

A streamlined, transparent workflow designed to take your custom cable project from drawing to delivery with precision.

Send Your Drawing

Upload technical files (CAD, PDF, or Sketch).

24h Engineering Review

Technical DFM feedback within 24 hours.

Quote Confirmation

BOM and pricing verification.

Prototype Production

Rapid sampling for validation.

Testing & Verification

100% electrical testing before approval.

Mass Production

Scalable assembly in Taiwan.

Logistics & Delivery

Global shipping and tracking.

DFM Support: Optimize for Production

Our engineers don't just build-to-print. We review every design for Design for Manufacturability to help you reduce costs and improve product lifecycle.

- - Connector & Terminal Cross-Referencing

- - Wire Gauge & Jacket Optimization

- - Custom Overmolding DFM Support

Featured Engineering Solutions

Industrial Test Clips

High-reliability alligator & Kelvin clips. 100% equivalents to Mueller Electric Clips for precision industrial testing.

Precision Test Leads

Flexible, lab-grade braided leads for precision electrical testing. Engineered for durability in telecom & industrial environments.

Modular Jack Connector

500+ models of RJ45 and modular jack connectors. High-speed data integrity for telecom and industrial networking hardware.

Custom Wire Harness

Precision multi-branch harnesses for industrial and radio applications. 100% Hipot tested in our ISO 9001 Taiwan facility.

Custom Cable Assemblies

Rugged IP67/68 waterproof, encoder, and coaxial assemblies. Specialized overmolded solutions for medical and automotive.

Custom Wire Harness & Cable Assembly Solutions?

Share your specifications, drawings, or application details, and our engineers will evaluate your project and get back to you within 24 hours.

Technical FAQs

Common questions from procurement and engineering teams.

How can I request a formal RFQ and technical review

You can submit your drawings (PDF, STEP, or CAD) through our RFQ portal or email them directly to our technical sales team. We provide Design for Manufacturability (DFM) feedback and cost estimates typically within 24-48 business hours.

What quality validation testing do you perform?

Every cable assembly and wire harness undergoes 100% electrical testing, including Hipot, continuity, and insulation resistance. We also perform pull-force and crimp-height validation as part of our standard Quality Control protocol.

Do you support High-Mix, Low-Volume (HMLV) orders?

Absolutely. While we support large-scale production, our manufacturing lines in Taiwan are optimized for the flexibility required by Medical and Industrial clients who often require smaller batches of highly complex, specialized connectivity solutions.

Are your alligator clips fully compatible with Mueller Electric standards?

Absolutely. Our clips are engineered to meet or exceed the technical specifications of Mueller Compatible Clips, including jaw opening, spring tension, and current rating.

What wire jacket materials do you offer for custom assemblies?

We work with a wide range of materials including PVC, Silicone (high flexibility), Teflon (PTFE), and Halogen-Free (LSZH) jackets to meet specific environmental or medical standards.

What is the typical lead time for custom prototypes?

Standard lead times for custom cable assembly prototypes are typically 1-2 weeks, depending on component availability and design complexity.

Do you assist with custom overmolding and tooling design?

Yes. Our in-house engineering team provides full DFM (Design for Manufacturability) support, including custom mold design and tooling for specialized connectors.

Build Your Cable Assembly

Have a drawing or a BOM? Fill out the form. Our engineers review every submission to ensure manufacturability and provide a quick quote.

0.8017578125

0.8017578125

1.5

1.5

1.5

1.5